More and more, environmental considerations necessitate the selection of hydraulic fluids and other lubricants that are free of zinc (widely used as an anti-wear additive), in addition to other heavy metals and toxic substances. These environmentally “friendly” choices should also be biodegradable, meaning that they will decompose into non-toxic elements within a prescribed time under prescribed conditions. For more information, refer to ASTM D6046-02 (2012), “Standard Classification of Hydraulic Fluids for Environmental Impact.”

To be classified as environmentally safe, a fluid must be readily biodegradable (more than 60% of the fluid must break down into innocuous products when tested in standardized laboratory tests over a 28-day period) and virtually non-toxic (more than half the rainbow trout fingerlings in a population must survive after four days in an aquatic solution with concentrations of the fluid greater than 1,000 ppm). A major benefit of these highly biodegradable fluids is that spills may have lower cleanup costs, depending on local regulations. Also, they are less likely to harm plant and animal life that comes in contact with a spill.

Family of Friendly Fluids

Hydraulic applications most considered environmentally sensitive include mobile equipment in general—with emphasis on agricultural, forestry, and construction machinery—as well as marine equipment used on fishing boats, off-shore drilling operations, and hydraulically operated bridges, locks, and dams. Other locations of note include commercial elevators and equipment in amusement parks.

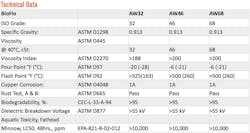

BioFlo AW Biodegradable Anti-Wear Hydraulic Fluids are formulated from readily biodegradable renewable resources, high lubricity base oils coupled with proprietary nontoxic anti-wear and anti-corrosion additives. These fluids can reduce operating temperatures, friction, and component wear in mobile and industrial hydraulic systems. High thermal and oxidative stability ensure long service life with minimal viscosity change over a broad range of operating temperatures.

BioFlo AW fluids—available in ISO grades 32, 46, and 68, and a sheen-free product—are suitable for use in ecologically sensitive applications. Synthetic formulations are available as in ISO grades 15, 22, 32, 46, and 68. In addition, BioFlo 68 is a fire-resistant fluid made from oleic vegetable oils that are compatible with most mineral oils and polyolester-based hydraulic fluids.

For more information, call ElementBio at (888) 995-7913, e-mail, or visit its website.