Wouldn’t it be great if leak-free connections could last forever? Great, yes. Realistic, no. The good news is that fitting designs have improved significantly over time, making it easier to assemble and reassemble most connections and conduct routine maintenance without increasing the risk of leak paths.

Two common types of fittings, however, generally rank poor for reusability. When dealing with tapered-thread pipe and JIC (Joint Industry Council) or 37° flare fittings, in particular, anyone doing maintenance on a fluid system should always ask: “Can I reassemble this fitting, or does it need to be replaced?”

Tapered-Thread Pipe Fittings

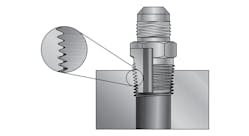

These torque-sensitive fittings have been around for many years, and if you’re working on old equipment, you’re likely to come across tapered-thread pipe fittings. They use a thread interface to make a metal-to-metal seal that generally is supplemented with the use of a sealant, such as tape or paste. Repeated assembly and disassembly can distort the threads, so it’s important to thoroughly inspect the threads for damage before reusing one of these fittings.

It would be wise to replace the male fitting any time you disassemble a tapered-thread fitting. But if you’re being frugal and want to reuse a fitting, here’s a quick way to determine if your reconnection will be leak-free:

1. Are more than six threads engaging? In other words, has the sixth thread from the end gone into the female port?

2. Does it take more than two turns of sealant tape to make a seal?

3. If you answered yes to either of these questions, you should definitely replace the fitting. Why? Because six or more threads indicate that the threads are already damaged, and more than two turns of sealant tape is likely to crack the female port. Also, be careful with the use of sealants on pipe threads. If some of the sealant gets into the hydraulic system, it can clog and cause other problems.

JIC 37° Flare Fittings

Tubing connections are made with cone, flare, and O-ring connectors. One of the most often used is the JIC 37° flare fitting, especially in high-pressure applications. Although industry generally accepts that JIC 37° flare fittings are reusable, they may not be reliable when reused. In fact, the JIC 37° flare fitting is the most questionable for reassembly.

JIC 37° flare fittings have a cone on the female adapter and a flare on the male adapter. The cone and flare surfaces seat against one another to create a complete mechanical seal between the male and female fitting. But each time the metal-to-metal seal is made, the cone and flare collapse more and more, causing the material to be cold-worked. The result is a harder metal, which makes each subsequent assembly more difficult and problematic on two fronts: a leaking seal and reduced flow due to excessive nose collapse.

How can you determine if a JIC 37° flare connection is reusable or not? Measure the amount of nose collapse and make certain that the hole diameter reduction is no more than 10%. For example, if the original hole diameter on a cone female adapter was 0.5 in. and has been reduced to 0.45 in. or smaller, you should replace the fitting. A pin gauge works well for a quick check.

Rob King is Engineering Supervisor at Parker Hannifin’s Tube Fittings Div., Columbus, Ohio. For more information on hydraulic tube fittings, call (614) 279-7070, visit www.parker.com/tfd, or email [email protected]. This material, from Parker’s techConnect blog, was used with permission from Parker Tube Fittings Division. Read more industry-specific topics on hydraulic connections, fitting applications, technical tips, and industry- and standards-related information by visiting Parker’s techConnect blog at tfdtechconnect.com.