Pneumatics technology continues to play an important role in many of today’s modern systems and manufacturing machines. The ongoing trend to build smaller machines by taking advantage of more compact components is a driving force behind the use of rodless pneumatic cylinders.

These efficient and cost-effective devices provide a high-performance method for moving loads in many different machine applications. Understanding the different types of rodless cylinders—as well as their operational and technical characteristics—can help design engineers select the right rodless cylinder for their specific requirements.

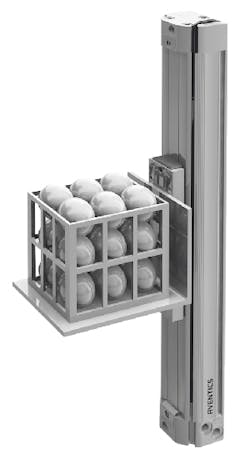

Rodless cylinders can be used in a wide variety of applications, including vertically mounted for uses such as parts elevators.

Development of Rodless Cylinders

Two kinds of pneumatic cylinders are currently in use: conventional cylinders with a piston and piston rod, and rodless cylinders. Because the rod extends out from a conventional cylinder barrel, the machine design must include enough open space to accommodate both the barrel length and the rod length as it is extended.

Conventional cylinders can have another limitation, depending on their size, stroke, and the load: deflection of the piston rod. If the load at the end of the piston rod is not supported by the machine, the cylinder can experience side load, which can cause misalignment and place excess strain on the bearings and pneumatic seals in the cylinder as the piston rod extends, and lead to poor performance and extra maintenance costs.

Rodless cylinders were developed to move similar loads, but for tighter machine spaces and motion requirements. In rodless cylinders, the risk of deflection can be virtually eliminated, because the load travels only the length of the cylinder, not beyond it. Many rodless cylinders incorporate load guidance features, such as slide bearings inside the cylinder or external rails with runner blocks to bear high loads with high repetitive precision. Given the high-quality materials used in constructing them, properly specified rodless cylinders can also offer long service life.

Heavier-duty rodless cylinders are available with external rail guiding.

All these features make rodless cylinders well-suited for use in a machine or system assembly with limited space, providing an efficient and highly effective pneumatic motion solution.

Main Types of Rodless Cylinders

There are several varieties of rodless cylinders in use today, including cable cylinders, flexible wall / bellows actuators, magnetically-coupled cylinders and slotted-type cylinders (also called piston-lug cylinders). The first two are more specialized in terms of their function and value.

- With cable cylinders, compressed air pushes a piston back and forth inside the cylinder barrel. A cable attached to one end of the piston loops around a sheave wheel mounted at each end of the cylinder. The other end of the cable connects to the other end of the piston, forming a closed loop. The cable has a carriage, or yoke, attached to it, and as the piston moves in one direction, the carriage moves in the opposite direction. These cylinders are well-suited to applications that call for higher cycle speeds and low linearity requirements, or where the load is already well-guided.

- Flexible-wall cylinders were originally developed for vibration isolation applications. They operate like a bellows. Rather than a solid metal tube, the cylinder is a reinforced rubber or polymer chamber with metal end covers, which expands and contracts as it is pressurized and vented, moving the attached platform or actuating the load. They can be used in similar applications that may use pivoting piston rod cylinders, but where compact overall length may be required, or the ability to move a load in an arc.

In scissor lifts for example, the connection plate of a flexible wall cylinder can move through the curved path to follow the scissor lift arm. It also collapses to a very small height when the lift is lowered, providing a more compact solution than a traditional piston-rod cylinder with pivot mounts. - Magnetically coupled rodless cylinders are piston-type cylinders but do not have a direct mechanical connection between the piston and the machine. Instead, a strong magnetic field binds the internal magnetic piston to an external carriage and the two move together. The outside of the cylinder wall provides a bearing surface for the carriage. Anti-rotation is generally accomplished by external guidance, which is frequently, but not exclusively, integrated into the actuator. Excessive force can lead to decoupling of the carriage from the piston, but since all external seals are static, external leakage and ingress of contaminants are both minimized.

- Slotted-type cylinders are a widely used type of rodless cylinder in fixed-location machine applications. The piston inside the cylinder housing is connected to an external carriage, usually by a mechanical coupling system. A longitudinal slot runs the entire length of the cylinder, through which the mechanical coupling extends. The slot is closed off for much of its length by two flexible metal sealing bands. The inner seal prevents air from escaping as the carriage traverses the length of the cylinder, while the outer seal protects the slot and inner band. These bands separate when the coupling and carriage passes by, maintaining the air seal while enabling the full motion cycle.

Slotted-type rodless cylinders had a reputation for leaking air when they were introduced decades ago. However, more recent designs incorporate stronger materials and design features in the piston carriage that virtually eliminate this issue. Taken together, these improvements have made rodless cylinders a reliable and efficient solution for many applications.

For example, some rodless cylinder manufacturers have added steel reinforcing wires into both the inner and outer seals, which are typically made of a flexible polymer. With the reinforcing steel, the seal is just flexible enough to be pushed out of the way by the piston carriage, but the steel wires bear the load rather than the more flexible seal, so that the seal maintains its integrity over the cylinder’s operational lifetime.

Advantages of Slotted-type Rodless Cylinders

The most significant advantage these types of cylinders offer is a compact source of load-bearing motion: the entire motion required is delivered within the overall length of the cylinder. In many applications—particularly those involving moderate to long strokes—rodless cylinders provide an optimum combination of compactness and value.

Although it is a compact motion source, that doesn’t mean that rodless cylinders have to be small. Select cylinder manufacturers have product lines with strokes ranging from quite short—as short as ½-in. stroke—to 32 ft. and longer.

They also offer high torque (side-load) capabilities, making rodless cylinders well-suited to moving loads in automation systems that span from lightweight to heavy. Most rodless cylinder manufacturers offer a range of products with a graduated series of cylinder bore sizes, which correspond to the loads they can support.

In addition, depending on the configuration, rodless cylinders can support high-speed motion: from 1 ft./sec to 21 ft./sec, making rodless cylinders ideal for applications such as film or paper cutting, to multi-axis motion systems.

Rodless cylinders also have a mechanical efficiency advantage compared to conventional cylinders. For piston rod and rodless cylinders, it’s well known that the piston’s diameter directly affects the amount of force or thrust it can provide. In a conventional cylinder, the piston rod takes up some of that piston area and reduces the available force to retract the piston rod. With rodless cylinders, there is no reduced area on one side of the cylinder. That means there are equivalent forces in two directions with one cylinder, so there is no need to change the working pressure on one side or the other to balance the forces.

Selecting the Right Rodless Cylinder

Unless an application calls for the specific capabilities of the cable or flexible wall cylinder, slotted-type rodless cylinders will typically provide a highly effective solution.

Awide range of manufacturers produces slotted-type rodless cylinders. Although these cylinders are relatively simple in design, there are technical features and engineering support tools that design engineers and OEM machine builders should consider when selecting rodless cylinders.

Oval piston shape—With circular pistons, all the side-load is carried by the bolt connecting the piston and the carriage. With an oval piston, the lateral torque is taken up by bearing surfaces on the oval piston and thus the load capacity is increased. In addition, this allows for a thicker and therefore stronger mechanical connection between the carriage and piston.

Some rodless cylinders utilize an oval piston design to provide increased load capacity and reduce side load.

Pneumatic cushioning—Cushioning capabilities in the cylinder reduce shock and wear-and-tear on cylinder components. Aventics, for example, has developed ideal cushioning capabilities, where the direction of travel of the piston is the same throughout the entire cushioning sequence (i.e., no piston bounce) and its velocity is exactly zero when it reaches the end of its travel. This can significantly reduce the sound of end-cover contact and extend the operational life of cylinder components, with the added benefit of minimized cycle time.

Built-in reliability features—Look for cylinders that incorporate elements designed to keep out contamination and extend reliable performance. Items such as wear-free stainless-steel cover strips over the cylinder slot; scrapers with spring-loading to keep the cover strip clean and prevent ingress of contaminants; steel-wire reinforced polyurethane sealing strips that resist stretching and maintain tight seals; and pistons and slides constructed of a single unit that enhance cylinder rigidity and machine uptime.

Ease of integration—Sometimes the simplest features make the difference. Some manufacturers offer cylinders with only one air inlet at each end of the cylinder; however, modern slotted-type rodless cylinders offer two air inlets at each end, allowing both cylinder connections to be made on one end of the cylinder, simplifying connectivity and installation and saving space. Other features such as integrated grooves for foot mountings and groves for incorporating sensor devices can help save valuable engineering and machine commissioning time.

Online sizing and selection tools—Intuitive step-by-step cylinder selection and sizing tools can save machine builders and design engineers valuable time. These online tools should include criteria such as stroke length, mass load and stroke time/speed/cycles per hour to help hone in on the correct product from the product range. Combined with the other design factors listed above, good sizing and selection tools help users quickly configure the best solution based on specific performance requirements.

Magnetic piston for proximity or infinite position sensing—Whether for traditional end-point proximity sensing, infinite linear position sensing for positioning/indexing applications, or for stroke/cycle counting for IoT predictive maintenance, built-in magnetic pistons allow non-contact sensing of the piston position.

Rodless cylinder shown with an externally mounted programmable sensor.

Compact and Powerful Performance

Rodless pneumatic cylinders are a cost-efficient, reliable and proven option to provide linear motion for a broad range of automated production machines and other systems. They support high-speed motion for fast cycle times and the ability to move loads ranging from lightweight containers and electronic components, to heavier masses such as those handled in palletizing machines. For systems that need to fit dependable linear motion into tight machine spaces, rodless pneumatic cylinders offer an effective solution that leverages the full value of pneumatics technology for motion applications.

Application Spotlight: Moving Train Doors with Ease

The compact size and proven efficiency of rodless pneumatic cylinders make them excellent tools for applications beyond automation machines. For example, Aventics recently launched the RTC-TD: a rodless cylinder designed to move train, subway, and other transport doors weighing up to 90 kilograms.

AVENTICS RTC-TD rodless cylinder shown in train door application.

There are specific requirements for this application: The cylinder needs to brake before reaching the door’s end position (particularly on closing) to prevent wear and ensure long service life for the drive and doors. Cushioning also minimizes the risk of passengers being trapped. On top of that, passengers should be able to open doors easily and quickly by hand in emergency situations.

Railway specialists at Aventics integrated cartridge cylinders into the end cover of their existing RTC rodless cylinder. These devices support the 3/2 directional exhaust, check-choke, and shuttle valves. The result: The drive is extremely vibration-resistant and is much more compact and lightweight than electromechanical and other pneumatic solutions.

The two-stage throttle with fixed throttle cross-sections is responsible for braking the door’s motion without any electronics or special controls. In the event of an emergency, such as a total power failure, the drive exhausts automatically to match the external air pressure, so that the door can be moved manually with ease.

The RTC-TD provides a lower-cost, nearly maintenance-free door movement solution, leveraging existing pneumatics systems already present on many transport systems.

Nathan Irvine is a product specialist at AVENTICS Corp., Lexington, Ky. For more information, visit www.aventics.com/us.