Download this article as a .PDF

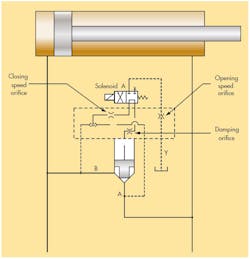

A large press uses a regenerative circuit to increase the closing speed of a ram. A pressure switch signals a PLC to close a logic slip-in cartridge valve so the ram can reach maximum tonnage. The press started having trouble developing enough tonnage when the logic valve did not close when Solenoid A was de-energized.

Technicians found the logic valve sleeve and poppet to be in good shape, and replacing the pilot valve did not fix the problem. They then removed the screw-in cartridge shuttle and found it damaged to the point that the floating ball was lodged in one end and would not move. They replaced the cartridge shuttle with a new one, but the new valve failed after only six to nine months of operation.

Any idea what was causing the failures?

Find the Solution

Think you know the answer to this month’s problem? Submit your solution via e-mail. All correct solutions submitted by July 3, 2017, will be entered into a random drawing for a $50 gift card. The winner will be notified, and his or her name will be printed in a future issue. Only one gift card will be awarded to any participant within a calendar year.

Congratulations to Nick Chasler, P.E., CMRP, Maintenance Reliability Engineer at Harley-Davidson Motor Co. A $50 gift card is in the mail to him.

Solution to Last Month’s Challenge:

Large-Plate Shear Problems

The shear blade problem straying from the backstops was caused by a lack of nitrogen pre-charge in the 2½-gal accumulator bladder. When the shear blade retracted, forcing the pullback cylinders to retract, a vacuum was caused in the rod areas, allowing air to enter past the cylinder rod seals. The cylinders were full of air, which allowed the blade to pull away from the backstops.