This file type includes high-resolution graphics and schematics when applicable.

Many of us working in the fluid power industry consider ourselves mechanically inclined. Concepts of pressure, force, flow, and torque are second nature. But the continuing influx of electronic components—especially transducers—into hydraulic and pneumatic systems makes knowledge of electrical terminology and concepts essential to job performance.

Pressure transducers serve the same function as a pressure gauge—the difference being that the gauge offers a visual indication of pressure whereas a transducer provides an electrical signal indicative of pressure. (Some pressure transducers have a digital readout to also provide visual indication.) To help explain some of the most common concerns surrounding pressure sensors, direct answers are given to the following frequently asked questions:

Is there a difference between a pressure transducer and a pressure transmitter?

When these terms originated, a distinct difference existed between the two. A transmitter was referred to as an instrument with a current signal, such as 4 to 20 mA, whereas a transducer had a voltage signal ranging from 0 to 10 V dc. Over time, these terms have become interchangeable. So in general, no, there is no difference, but the answer may depend on whom you talk to.

One problem with pressure transducers is that they normally don’t show you pressure. Is there a way to see what the pressure is without having to install a new indicating transducer?

Of course, Noshok and other manufacturers offer transducers with an LED indicator to display pressure right on the transducer. But for existing applications, Noshok’s 1800 series digital indicator can easily be installed between a transducer’s DIN 43650A output connector and cable. In fact, it can work with any brand transducer with a DIN 43650A connector and sufficient power-supply voltage to drive all instruments in the loop.

Another advantage is that it can be transferred from one transducer to another. Therefore, if a transducer becomes damaged, the indicator can be reused on a new transducer, provided it also has the DIN 43650A connector.

Pressure transducers are mechanical structures, so they respond not only to changes in pressure, but also to changes in temperatures. Extreme temperature fluctuations may change a transducer’s output signal even though pressure remains constant.

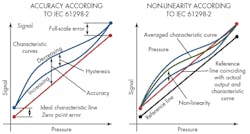

Accuracy of a pressure transducer generally takes into account nonlinearity, hysteresis, and non-repeatability. Nonlinearity is the maximum deviation from the average characteristic line to the reference line. Hysteresis is the maximum difference between the characteristic lines recorded at increasing and decreasing pressure. Non-repeatability is the maximum deviation between values of output for any single input of multiple cycles, considering decreasing and increasing pressures separately.

Because temperature has such a major impact on transducer accuracy, can I use a pigtail siphon to help keep hot hydraulic fluid from affecting the transducer?

Sure. Pigtail siphons are typically used in steam applications, but they can also be used in systems where hydraulic systems may run hot. The pigtail helps cool the hot fluid before it reaches the transducer, and can help dissipate fluid shock.

What are RFI, EMI, and ESD, and why are they important?

Radio-frequency interference (RFI) and electromagnetic interference (EMI) are types of electrical noise, or interference. RFI frequently comes from two-way radios, while EMI often is generated by ac electric motors. Electrostatic discharge (ESD) is the sudden flow of electricity between two electrically charged objects when they touch each other. CE-compliant devices incorporate protection techniques and components to minimize most of these types of interference.

Can orifices and snubbers be used with pressure transducers?

As with other pressure measurement instruments, including gauges, pressure pulsations and spikes may become problematic for pressure transducers. Measuring the pressure of an incompressible fluid introduces the possibility for pulsations and spikes, which can damage pressure transducers. A factory-installed orifice in the pressure connection can protect the transmitter from damage. Although this solution is usually adequate, if there’s potential for the orifice to become clogged by dirt in especially dirty hydraulic fluid, we recommend installing a piston snubber.

What is the difference between proof pressure and burst pressure?

Proof pressure, which scales higher than the full-scale pressure point, is the maximum pressure the transducer can withstand without affecting its performance and calibration. Burst pressure, on the other hand, represents the highest pressure possible before the transducer’s pressure chamber could leak or rupture. Sometimes proof and burst pressure ratings are identical.

Michael Lancaster is engineering manager at Noshok Inc., Berea, Ohio. For more information, call (440) 243-0888, or visit www.noshok.com.