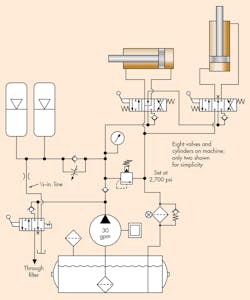

A large crawler machine for transporting missiles has a hydraulic system to deploy various clamps, ramps, and lift cylinders—all controlled through a bank of manually operated mobile valves. Accumulators supplement pump flow to help move several large cylinders quickly until they approach their load. The operator then feathers the valves to produce slower motion as needed.

After starting the machine’s diesel engine, operators position the system for operation. A two-position detent directional valve next to the main valve assembly is then shifted to block the pump from returning to tank and charge accumulators to operating pressure.

A problem occurred at the missile launch pad, and technicians had to replace the pump. It was a windy day, with dust flying everywhere. They were able to get the unit up and running and returned it to the storage building. The next time they used the machine, they were unloading a missile when both doors blew off the hydraulic reservoir and dumped 300 gallons of oil on the crawler and surrounding area. They were feathering one of the valves when a large swishing sound was heard, followed by the doors being blown off.

Any idea why this happened?

Find the Solution

Think you know the answer to this month’s problem? Submit your solution via e-mail. All correct answers submitted by Jan. 8, 2018, will be entered into a random drawing for a $50 gift card. The winner will be notified, and his or her name will be printed in a future issue. Only one gift card will be awarded to any participant within a calendar year.

Congratulations to D. Aroan, of Tamil Nadu, India, whose name was picked at random from those who correctly solved last month’s challenge. A $50 gift card is in the mail to him.

Solution to Last Month’s Challenge:

Tube Bender Has Drift Problem

Closed loop control for positioning hydraulic actuators requires all the components to be accurate. The D-03 proportional valve with overlapped spools but no spool-position feedback has about ±4% positioning accuracy. The solution was to replace the three proportional valves with zero-lapped spools and LVDTs for spool-position feedback. The valves also had on-board electronics, and the problem was solved.