Noise, heat, vibration, and leakage can interfere with the proper operation of a hydraulic system or provide warning of future problems. Maintenance and troubleshooting personnel can help avoid these problems — simply by using their natural senses of sight, touch, and hearing in an organized pattern.

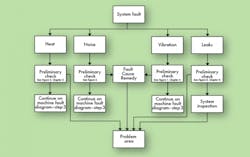

As previously mentioned, a hydraulic system may malfunction or operate improperly because of one or more problems located away from the system. One example would be cavitation or aeration in a pump located in a remote pump house. Under such conditions it might help to use the Fault, Cause, Remedy (FCR) review process outlined in Figure 4.

Seldom is an entire system at fault even though several malfunctions may occur in close sequence. In a large system, first examine that part of the hydraulic installation where the faulty component is mounted. Follow these steps:

1. Determine which of the four basic problem symptoms seems to apply: excessive heat, noise, vibration, or leakage. If the problem is heat, see Figure 4. Vibration and leakage investigation will be covered in Chapter 5.

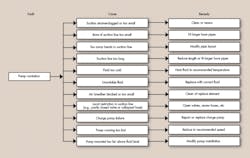

2. If excessive noise appears to be the problem, consult the chart in Figure 5. It provides a selection process that considers many common conditions associated with excessive pump noise.

3. If, after this examination, you conclude that noise is caused by pump cavitation or aeration of fluid, check the system following the suggested Fault-Cause-Remedy sequences shown in Figure 6.