The most common use for accumulators is to supplement pump flow. Some circuits require high-volume flow for a short time and then use little or no fluid for an extended period. Generally speaking, when half or more of the machine cycle is not using pump flow, the application is a likely candidate for an accumulator circuit.

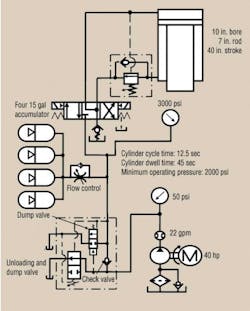

The circuit shown uses several accumulators to supplement pump flow because the dwell time is 45 sec out of the 57.5-sec cycle time. This circuit’s 22-gpm fixed-volume pump operates on pressure during most of the cycle to fill the cylinder and the accumulators. Without the accumulators, this circuit would require a 100-gpm pump driven by a 125-hp motor. The first cost of the smaller pump and motor plus the accumulators is very close to that of the larger pump and motor. However, energy savings over the life of the machine make the pictured circuit much more economical.

One drawback of using accumulators to supplement pump flow is that the circuit must operate at a pressure higher than needed to perform the work. In the circuit, a minimum of 2000 psi is necessary to perform the work. This means the accumulators must be filled to a higher pressure so they can supply extra fluid without dropping below the minimum pressure. This circuit uses 3000-psi maximum pressure to store enough fluid to cycle the cylinder in the allotted time and still have ample force to do the work. The flow control in the circuit is necessary to keep the cylinder from cycling too rapidly. An accumulator discharges fluid at any velocity the lines can handle while operating at whatever the pressure drop is when a flow path is opened.

The pictured circuit uses a fixed-volume pump and an accumulator unloading-and-dump valve. The valve forces pump flow to the accumulators when pressure drops approximately 15% below its maximum set pressure. At set pressure, the unloading valve opens and all pump flow bypasses to tank at 25- to 50-psi pressure drop. While the pump is bypassing, a check valve keeps the accumulators from unloading to tank. The dump valve (which is a high-ratio, pilot-to-close check valve) is held closed by pump idle pressure until the pump shuts down.

This information was excerpted from Chapter 16: Accumulators of our Fluid Power Ebook Edition 1. Read the entire chapter here.

The following is a brief round-up of some of the latest accumulator products available in the fluid power marketplace: