Got questions about hydraulic proportional valves and hydraulic servo valves? So do we.

But we also have answers. Electrohydraulic expert Jack L. Johnson, P. E., fields some of the recurring questions he encounters in his many educational sessions about closed-loop electrohydraulic control, including those related to hydraulic proportional and servo valves.

Q: I’m confused about servo and proportional valves because the differences don’t seem clear cut. What, exactly, is the difference between a servo and proportional valve?

A: The generic descriptive term that applies to this class of valves is, “continuously variable, electrically modulated, hydraulic directional control valves.” Germans use the term stetigventil — a continuously differentiable valve, and servo valves and proportional valves fall within this generic valve type. Unfortunately, we have no single word in English to cover these valves. The generic term should be “proportional valve,” with two subcategories: servo valves and proportional valves.

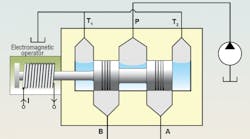

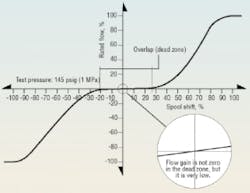

The illustration to the right represents a zero-lapped (servo) valve, where even the most minute movement of the spool opens flow paths. The lower drawing in the illustration represents a proportional valve, which exhibits 3% or more overlap between the spool and valve lands.

An extensive research project at the Fluid Power Institute was conducted to determine how a user could distinguish between a hydraulic proportional valve and a servo valve. We used electronic enhancements to determine the extent to which a proportional valve could be made to perform like a servo valve. Performance characteristics and construction and manufacturing methods were examined. The most significant discriminator was the amount of center overlap. We eventually defined a servo valve as one with less than 3% of center overlap, whereas a proportional valve has center overlap of 3% or more.

Read more from Johnson on defining the differences between proportional and servo valves.

Q: What is a valve overlap?

A: Valve lap, or valve overlap, refers to the amount of spool travel from the center position required to start opening between the powered input port and the work (output) port or the tank port.

A zero lapped valve is one in which any tiny, differentially small amount of spool shift, either way, starts the opening. However, there is no contact between the O.D. of the spool and I.D. of the bore. And even zero lapped valves have some slight amount of overlap. Nonetheless, the zero-lapped term persists.

Q: What is valve null?

A: Valve null is a specific point of a hydraulic servo valve’s pressure metering curve where the two deadhead (blocked port) work port pressures are equal. Servo valves are equipped with a mechanical adjusting device so that with no electrical power applied (connector disconnected from the valve), a spring or magnetic force can be changed to make the two work port pressures equal. That is normally where the factory adjusts a valve during final test, assuming it will be used on an equal area cylinder.

If the application has an unequal area cylinder, the user removes the valve connector (which will probably cause the piston to creep), and changes the null adjustment until the cylinder stops moving. Of course, with the cylinder stopped, this will result in unequal pressures in the cylinder due to the piston area differences and affected by any non-zero load.

Q: What is null shift in a valve?

A: Null shift is an effect that causes the valve to drift from its null point. For example, if a valve is nulled, and the temperature or supply pressure changes, the valve will no longer be at its null point. Either the current or the mechanical null screw will have to be adjusted in order to re-acquire the precise null point. The important issue to remember is that anything that causes the null of the valve to shift results in an error in the closed-loop system, such as a positional servomechanism or a pressure control system. Null shift is important only in zero-lapped valves.

READ MORE: How to Interpret Valve Specifications

Q: Why is valve overlap the single most important discriminator between servo and proportional valves?

A: Simply put, the Fluid Power Institute study designated servo valves as having near-zero overlap and proportional valves as having significant overlap. Therefore, a so-called zero-lapped valve can be given servo valve status and still accommodate normal manufacturing tolerances because it allows up to 3% overlap. Furthermore, you can rarely distinguish any system performance degradation caused by that slight amount of overlap. In fact, some amount of overlap is desirable because it reduces the amount of spool-to-bore leakage.

Whenever performance specifications contain requirements of a specific accuracy, a hydraulic servo valve is probably going to be required. For example, a user may have a requirement that a cylinder must have total travel of 24 in. while propelling a 10,000-lb. load at a speed of 15 in./sec, and must achieve a final position with an error not to exceed 0.020 in. This kind of performance specification begs for a servovalve and motion control design methodology.

The most accurate systems are called null-seeking. What this means is that when the controlled output — say, the position of a cylinder — is in the desired position, the valve spool is near its center position. To achieve great accuracy in positioning, any small disturbance of the cylinder’s position (caused, for example, by a change in external load) must be immediately counteracted by a commensurately small move in the spool to overcome the disturbance. Such null-seeking operation is also required in many pressure control systems.

Zero lap in the valve means it can react and do its correcting job regardless of the direction of the disturbance and no matter how small it may be. Again, the term zero-lapped is an idealized term; the real valve will likely have a slight amount of overlap.

READ MORE: Understanding Electrohydraulic Valve Types

Q: I am trying to decide which type of valve to use in my closed-loop application, a servo valve or a proportional valve. I am impressed with the performance of a servo valve, but I am concerned about its high pressure drop. How do I decide between the two?

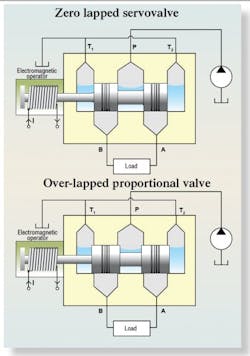

A: The pressure drop across the valve is a source of confusion at worst and misconception at best. All servo valves are flow rated at 1,000 psi (7 MPa according to ISO 10770-1, which converts to about 1,015 psi) and have been for several decades. The rated flow of a servo valve is that flow which is measured with 1,000 psi differential pressure from the pressure port to the tank port while the work ports are looped. On the other hand, proportional valves are flow rated at 145 psi (1 MPa in ISO 10770-1).

This difference in flow rating pressures leads the uninitiated to conclude that hydraulic proportional valves have less pressure drop. This is simply false. When sizing the valve, the sizing process calculates the required valve flow coefficient, that is, the KV value. It makes absolutely no difference which valve type you are planning to use, the properly sized proportional valve has exactly the same KV value as the properly sized servo valve!

They will have the same sized flow area and the same pressure loss in the application. There is absolutely no pressure drop advantage of one over the other! The two valves don’t have different flow ratings because they have different amounts of opening, but because their flows are rated at different pressures. The refusal of the industry to adopt publication of their valve KV values proliferates the confusion.

Q: Why do so many proportional valves have lower hysteresis than servo valves do? Aren’t servo valves supposed to be “more precise?”

A: Hysteresis is the property of some input-output devices, such as valves, sensors, magnetic devices, mechanical linkages, and such that causes the characteristics with increasing input not to track the same path as with decreasing input. The two common mechanical causes of hysteresis are static friction and backlash, and there is also magnetic hysteresis.

Electrohydraulic valve hysteresis is caused by all three effects and is, therefore, an important performance parameter. Hysteresis causes errors in the servo system because it has the effect of creating a null shift in the valve, depending on the direction from which the targeted output, say position or pressure, is approached. Hysteresis is very undesirable, but inevitable in valves.

As for the issue with “cheap old proportional valves” having less hysteresis, that is often true. The reason is that many servovalves use a feedback wire or spring to achieve proportioning of spool position. This is purely mechanical linking between the torque motor and the main spool. There will be mechanical and magnetic hysteresis effects. A typical figure in manufacturer’s literature may list hysteresis as less than 2%.

Many proportional valves use an LVDT spool position sensor with electronic feedback, and the result is a “tighter” spool position control loop and less hysteresis. Some multistage servo valves use LVDT spool position control. They too, will have lower hysteresis, and a common published value is less than 0.5%. It takes extra special test techniques to find the true amount of hysteresis in such valves, because it is so small. When the valve threshold is low enough, any resulting limit cycling with PID control is likewise low enough to be unnoticeable.

READ MORE: How Bode Plots Describe Servo Valves Specifications

Q: I have heard that proportional valves have better contamination tolerance than servo valves, and that some designs are better “dirt eaters” than others. What is your assessment of these claims?

A: I have heard those same claims, but I remain skeptical. The arguments that I have heard usually focus on a single feature of a given design and make the claim that because that feature is better at rejecting contaminants, the whole valve is, therefore, better. For example, the advocates of direct acting valves make the claim that “there are no tiny nozzles to plug up.” This argument is specious at best, because the nozzles (flapper-nozzle design), being greater than 0.002 in. (50 ∝m) in diameter require gigantic contamination particles to do the plugging up. I maintain that any system that is circulating 50 ∝m particles has many more serious problems, not just with the servo or proportional valves.

The fact is that contaminants affect valves in other ways. If contaminants are abrasive, they will erode surfaces and metering edges. With modern machining methods, servo and proportional valves have the same spool to bore clearances, and a piece of hard contaminant can create spool lock up in either type of valve, or any type of valve, for that matter.

This subject is very important, and other people have much more expertise than I. But I see one basic problem with the claims of the advocates: There is no internationally standardized, objective test method for determining the contamination tolerance of valves. Attempts to develop such standards have met with failure from lack of resolve at the international level.

Until that standard emerges, I remain skeptical, and users are at the mercy of their suppliers and their own wits to keep them out of trouble. And it remains absolutely true that clean fluid is everybody’s friend. Follow proper cleanliness procedures so that the filters become your dirt eaters in the system — and maintain that cleanliness level.

Q: What is PWM?

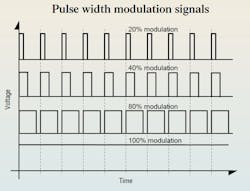

A: PWM stands for Pulse Width Modulation. It is an on-off method of controlling output current and voltage (power). The output stage of the PWM amplifier is a transistor on-off switch. Proportional control is achieved by controlling the amount of on time to off time. The rate at which the switch turns on and off, called the PWM frequency, is normally fixed (from 30 or so Hz to as much as 40 kHz — electronic circuit designer’s choice), and well above the frequency at which the hydromechanical system can respond. The valve and actuator, then, respond to the average current, not the instantaneous current.

For example, suppose the PWM frequency of a certain PWM valve driver is, say, 100Hz. The period, then, is 0.010 sec; that is, 10 msec. If the on-time is 2 msec, and the off-time is 8 msec, the valve will respond to an input of 20% of maximum. We say that is “20% modulation.” If on- and off-times were both 5 msec, the modulation would be 50%, and thus we would expect the valve spool to be shifted 50%, more or less.

PWM has become the power amplification method of choice for controlling proportional solenoids because they often require 3 or 4 A of current and perhaps as much as 30 W of power. Reducing the heat produced in the amplifier without sacrificing output power is a great energy saver. If the frequency of the on-off switching is matched with the proportional solenoid and valve, there can also be some dither benefit that has the effect of reducing the effects of static friction.

Dither helps to reduce hysteresis because it keeps the mechanical moveable members of the solenoid in a constant state of vibration, but not so much that the output actuator vibrates palpably.

Q: My electrical guy tells me he can couple the servo valve from manufacturer X to the output of a servo amplifier from manufacturer Y, and he expects it to work just fine. We also have a proportional valve from manufacturer Z, but he says we can’t use a proportional valve amplifier from anyone except manufacturer Z. What am I missing here?

A: One of the uncelebrated realities of servo amplifiers is that they are much simpler than proportional amplifiers. This makes servo amplifiers more universal, so just about any servo amplifier will drive any hydraulic servo valve. The reason is that most servo valves use a torque motor as their electromagnetic actuator, so they can reverse direction by merely reversing the direction of the current. The most important parameter is the amount of current the amplifier can supply to the torque motor relative to the current required by the torque motor.

On the other hand, most proportional valve amplifiers must accommodate LVDTs, which are used for spool position sensing in the proportional valve. LVDTs are AC devices that require special signal conditioners that supply high frequency AC excitation (upwards of several kHz) and then demodulate the output to develop a DC voltage proportional to spool position.

Plus, many proportional valves have two solenoids to achieve both directions of spool shift, so electronic circuits must steer the signal so that current of one polarity goes to one solenoid while current of the opposite polarity goes to the other solenoid.

Torque motors will usually operate with no more than 100 mA, and they can be shifted with only a few mW of power. The bottom line is that the proportional amplifier must be matched to a specific line of valves and is likely not to work on any other valves.

READ MORE: Proportional valves help recover energy in refuse incinerator