Parker Hannifin Corp. continues to refine its hybrid drive technology, which is an advanced hydromechanical series drive system designed to significantly reduce fuel consumption and increase productivity in vehicles with high start-and-stop applications.

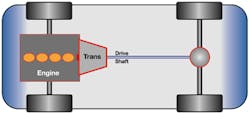

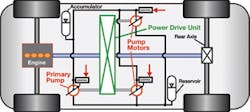

Parker’s hybrid drive system for refuse trucks replaces a vehicle’s conventional transmission with a series hybrid drive system that marries the variable features of a hydrostatic drive with a mechanical drive that performs best at highway speeds. Coupled with brake energy recovery technology, it is suitable for severe-duty applications.

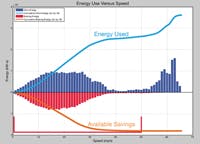

The Parker hybrid drive system offers fuel savings, reduced emissions, and dramatically reduced brake wear. Refuse vehicles equipped with the hydraulic hybrid drive system have achieved fuel savings of 30% to 50% during track testing and actual field trials of refuse collection cycles. Vehicles can use full engine power at any time, but the system’s design optimizes efficiency by matching engine load with vehicle requirements.

The hybrid drive system is built around Parker’s proprietary Power Drive Unit (PDU), for high power, high start-and-stop applications. An onboard controller coordinates pumps, hydrostatic motors, and accumulators to power the vehicle when in hydrostatic mode while collecting refuse. Instead of solely using diesel engine power, accumulated energy from the vehicle’s braking system is stored and used to power the truck each time it accelerates. As it reaches highway speed, the PDU transfers from hydrostatic drive to mechanical drive to maximize operational efficiency.

Since the system’s inaugural showing at the 2006 Waste Expo show in Las Vegas, Parker has continued to refine the hybrid drive to optimize system performance and reliability. The latest version, featuring a patent pending design for packaging mechanical, electric, and hydraulic components, will be unveiled at WasteExpo, June 9-11 at the Las Vegas Convention Center.

Parker’s stage gate product development process integrates computer modeling, dynamometer testing, lab testing, and full vehicle on-road operation to validate performance per user criteria, such as functionality, quality, reliability and added value.

Although most testing is done at Parker’s engineering offices and labs, Parker is also evaluating prototype vehicles through a variety of acceptance tests that replicate real-world operation. A state-of-the-art vehicle proving ground contains all road and driver conditions required to validate vehicle drive performance and durability. Trucks are operated 24/7 in a controlled environment with professional drivers, mechanics, and fleet managers evaluating fuel economy, acceleration, braking, responsiveness, road loads, vibration, gradability, and other conditions that are encountered in refuse collection service.

In addition to hybrid drive systems for refuse collection vehicles, Parker is developing variations of the hybrid drive for other on- and off-highway applications with high startstop duty cycles that require significantly different torque and packaging solutions.

For information, contact Vance Zanardelli, Energy Recovery Business Unit Manager, at (662) 890-5267 or email [email protected]. Visit www.hydraulicspneumatics.com to see additional images, including engineered drawings of the PDU and drive shaft.