This file type includes high resolution graphics and schematics when applicable.

When Airbus first decided to begin the engineering challenge to build the world's largest commercial aircraft, they knew that weight and component volume would be a critical factor in the overall design. They contacted several aerospace hydraulic suppliers and began a coordinated engineering evaluation of the latest hydraulic-system technologies and their advantages. The result of the system design study supported the decision to go with a 5000-psi hydraulic system. From this coordinated effort (based at Airbus' headquarters in Toulouse, France), the team undertook a four-month plateau phase, in which a component specifications criteria was developed. Ultimately, Eaton was selected to design and supply the hydraulic power-generation system and later the aircraft's fluid-distribution system.

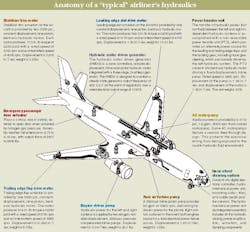

Few other industries focus on weight as much as aircraft manufacturers, and with good reason. Every extra pound contributes to fuel costs - and impacts the bottom line for the airlines. Since the 1970s, military aircraft have been using 5000 psi hydraulic systems, which use lighter-weight components to actuate the flight control surfaces. Passenger aircraft have been relegated to 3000-psi hydraulic systems (with the exception of the Concorde, which features a 4000 psi system). Now Airbus' new A380, a monster of a plane, is changing all that.

A dual-architecture system

In designing the A380, Airbus created a dual-architecture system for the flight controls. Four independent primary flight-control systems will reside on each A380: two powered hydraulically and two powered electrically. Any one of these four systems can operate the aircraft, bringing the redundancy in flight control to a point unequaled on any other plane - commercial or military.

The two hydraulically powered systems drive conventional servo-controlled actuators, and are the primary operating flight-control circuits. This type of flight-control system — found on most commercial aircraft today — is referred to as a fly-by-wire system, because it is controlled electrically.

The two circuits powered electrically drive nonconventional actuators known as electro-hydrostatic actuators (EHAs). These systems are truly back-up or operate on-demand in unusual flow demand situations. This type of flight control system (in addition to being fly-by-wire) is referred to as a power-by-wire system, as it is powered electrically.

Although Airbus feels that power-by-wire is probably the next technology for commercial aircraft flight controls, it is only using this technology for back-up to the main control system. For the demanding daily operation that a commercial aircraft's primary flight control system is subjected to - especially one this size with the number of very large control surfaces - the conventional hydraulic-powered servo-controlled actuator system is still preferred.

The performance of the EHAs on the A380 will help provide operational data and determine how quickly a technology transition in primary flight control will occur.

Notes John Halat, director of research and new product development for Eaton, "Hydraulics is the requirement on the A380, simply due to the massive areas being articulated. The EHAs are designed to be used in limited situations, a total of hundreds of hours maximum. On the other hand, the hydraulic pumps are rated to 35,000 hr mean time between failures."

Although the A380 will certainly be more electric, it will also be a much more hydraulic aircraft. The eight engine-driven pumps rated at 5000 psi will deliver 48 gal of hydraulic fluid per minute, producing a 1120-hp system - more than three times the hydraulic system horsepower generated on an Airbus A340.

Hydraulic system

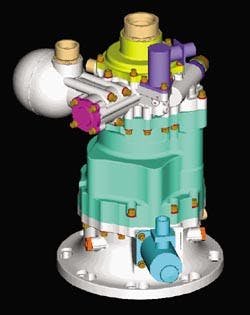

Airbus selected Eaton to provide the 5000-psi hydraulic power generation for the A380. The system consists of eight Vickers PV3-300-31 engine-driven hydraulic pumps, along with four AC motorpumps and the associated electronic control and protection systems. The pumps are pressure-compensated, variable displacement type, and deliver 42 gpm at 3775 rpm. Their displacement is 47 ml/rev.

Two unique aspects set this pump apart. First is the disengagement clutch, a feature not currently found on any commercial or military aircraft pump. In cases where a pump is malfunctioning while the plane is on the ground, the clutch can segregate that pump from the system. This allows the plane to be dispatched using the remaining seven pumps (seven pumps are needed for normal flight operations; the remaining pump is redundant, for safety). Typically, in the event of a grounded aircraft, the airlines would have to accommodate more than 500 passengers - which could be very costly to the airline. In flight, the pump can be detached in case of failure, so it won't contaminate the rest of the system. Explains Phil Galloway, engineering manager for Eaton, "The pump can't re-engage except on the ground, via manual means."

The other important feature of the PV3-300-31 is its extremely low noise and pressure pulsation. Pressure in a given 5000-psi system might vary from 4900 to 5100 psi, due to normal pressure pulsations created from the pump. On aircraft, the variation has typically been 10% or less, improving to 5% with more recent models. In order to improve reliability and minimize fatigue throughout the aircraft's fluid distribution lines, Airbus asked for a pump with ±1% pulsation.

Eaton responded with a pump model that features a built-in attenuator and an 11-piston rotating group - meeting the Airbus goal and resulting in one of the lowest noise pumps in the market.

Galloway explains that making the switch to 5000 psi isn't as easy as pulling different parts off the shelf - there are some serious pump design issues at higher pressures, including:

- material selection,

- stresses,

- deflections,

- pressure time velocity factors,

- pressure balances,

- efficiency, and

- pressure pulsations.

"Above 3000 psi, using aluminum as a pressure vessel becomes risky," says Galloway. "5000 psi systems almost exclusively rely on steel or titanium. To minimize stresses, the sizes of passages can be reduced. Computational fluid dynamics is also used to minimize pressure drop in critical areas."

With higher system pressures, "internal" pump leakage naturally increases - which decreases volumetric efficiency. But, because of improved oil film thickness and resulting reduced sliding friction, torsional efficiency tends to increase.

Pulsations can be minimized with the use of pulsation attenuators, essentially fluid volumes added to the outlet line of the hydraulic pump. The size of the attenuator is a function of the size of the pump and the amount of attenuation desired. The drawback to large attenuators is that the weight can be significant, as a high pressure volume is required.

Inside the plane of the future

The A380 has more impressive features than just the hydraulic system. Its huge size opens possibilities that are unthinkable on smaller planes, such as the comfortable premium class setup shown. (Of course, whether the airlines choose to still cram us in like sardines in coach is another story.) Other interesting facts about the new plane:

• Laser welding will be used to attach the longitudinal reinforcements of the lower fuselage shell instead of traditional riveting. This not only saves weight, but is a faster manufacturing process.

• The plane will comply with the strictest local noise regulations, yet it will make less noise than its closest competitor while carrying 30 to 50% more passengers.

• It will be able to taxi using only two of its four engines, if required.

• The A380 will be the first long-haul aircraft to consume less than three liters of fuel per passenger per 100 km. Airbus claims that this rate of fuel burn is comparable to that of a mid-sized automobile.

• The cockpit will be located midway between the two decks, allowing the pilots to sit closer to the aircraft's center-line. Cameras on the tail fin and belly will allow accurate placement of the plane.

• Although large, the plane will not require reworking of current airport facilities. The 20-wheel main landing gear distributes weight in such a way as to remain within the parameters of other in-service aircraft. Two decks and wide forward stairs will allow for rapid loading and unloading, even in cases where only single deck access is possible.

This file type includes high resolution graphics and schematics when applicable.