Camping means different things to different people. For some, it is sleeping on the ground — with or without a tent — and cooking over an open fire. For others, it means taking a recreational vehicle (RV) out to wide open spaces and still have all the comforts of home — air conditioning, microwave oven, washer and dryer, and even satellite TV.

Of course, not all RVs have this multitude of amenities, but for those that do, it can be difficult to fit all these creature comforts into a vehicle narrow enough to travel standard roads and still have living space. These luxury RVs have slide-out sections that nearly double the width of living space. Even if these sections could be pulled out manually, luxury demands that they extend and retract with just the flip of a switch.

Smaller RVs — about 6500 lb or less — with slide-out sections use electromechanical assemblies for extension and retraction. Larger, heavier vehicles, require the power of hydraulics because electro-mechanical systems would be larger, heavier, and more costly than a hydraulic system. Furthermore, the hydraulic system's power unit can be used not only for the slide-out section, but for powering cylinders of a leveling system as well. So instead of requiring an electric motor for every electromechanical function, the hydraulic solution can use a single electric motor and pump for all functions by using valves to route hydraulic power to the appropriate actuators.

High force from hydraulics

The slide-out units and leveling systems are actuated by double acting hydraulic cylinders, which typically have bores of 3¾ in. and strokes of 12 to 30 in. The systems generally operate at pressures from 1750 to 2250 psi. Depending on system pressure and bore, each cylinder can generate 12,000 to 63,000 lb of force. However, stroke speed is relatively slow — roughly 10 in/sec. This means the hydraulic power unit (HPU) for the system need only deliver about 1 gpm of flow, but at high pressure.

Once the sliding section is fully extended, either hydraulic check valves or mechanical latches secure it in place. Leveling systems generally work by depressing a rocker switch to extend the cylinder. When the switch is released, a load-holding check valve secures the cylinder in position. More sophisticated systems incorporate level sensors for automatic leveling. However, whatever the setup, the leveling systems can use the same HPU as that used for slide-

load-holding check valve secures the cylinder in position. More sophisticated systems incorporate level sensors for automatic leveling. However, whatever the setup, the leveling systems can use the same HPU as that used for slide-

63,000 lb of force. However, stroke speed is relatively slow — roughly 10 in/sec. This means the hydraulic power unit (HPU) for the system need only deliver about 1 gpm of flow, but at high pressure.

Once the sliding section is fully extended, either hydraulic check valves or mechanical latches secure it in place. Leveling systems generally work by depressing a rocker switch to extend the cylinder. When the switch is released, a load-holding check valve secures the cylinder in position. More sophisticated systems incorporate level sensors for automatic leveling. However, whatever the setup, the leveling systems can use the same HPU as that used for slideout sections because the two functions do not have to occur at the same time.

Compact HPU keeps it simple

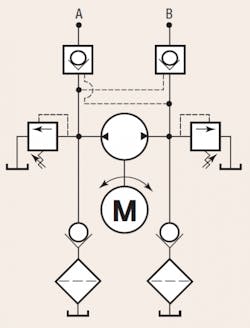

The bidirectional motor-pump not only simplifies the hydraulic circuitry, but eliminates the expense and related costs of having a directional control valve. An added bonus is that even though the SMR operates from a vehicle's 12-V dc power, it doesn't have to have electricity to operate. It's motor has a double-ended shaft, so a user can connect a cordless drill to the shaft extension to drive the hydraulic pump. This is a more convenient and cost-effective solution than using a hand-powered pump for backup operation.

Normally, a compact dc power unit requires electric power for the motor, and an electrical signal for a directional control valve. However, the SMR has a bidirectional motor-pump, so reversing polarity of electrical power to the motor reverses flow direction from the pump.

The SMR delivers flow to 1.0 gpm at 1500 psi and accommodates working pressure 2500 psi. Its motor requires 12 V dc at up to 180 A.

For more information on the SPX Smiths dc power unit, call (815) 873-3379 or visit www.spxfluidpower.com