Correctly sizing an electric motor for a hydraulic power unit is a straightforward procedure. And if load pressure and flow remain fairly constant, determining the power requirement is relatively simple by using the familiar equation:

hp = Q × P / (1714 EM)

where:

Q is flow, gpm (and accounts for the pump's volumetric efficiency),

P is system pressure at full load, psi, and

EMis the pump's mechanical efficiency

For example, assume an application requires a flow of 13.7 gpm at a maximum pressure of 2000 psi, and with a pump efficiency of 0.80. From the equation above:

hp = 13.7 × 2000 / (1714 × 0.80)

= 20 hp.

It may seem that a gas or diesel engine as the prime mover would have the same power rating as an electric motor. However, the general rule of thumb is to specify an internal-combustion engine with a power rating 2 1 /2 times that of an equivalent electric motor. This is primarily due to internal combustion engines having different torque-speed relationships than electric motors. Examining the different torque characteristics will provide the understanding to make a choice based on solid reasoning — rather than putting faith in a rule of thumb.

Pump torque requirements

Power, of course, is the combination of torque and rotational speed:

hp = (T × n) / 5250

where:

hp is horsepower

T is torque, lb-ft, and

n is rotational speed, rpm

A pump's torque requirement is the main factor that determines whether a motor or engine is suitable for an application. Speed is less critical, because if a pump runs slowly, it will still pump fluid. However, if the prime mover does not develop enough torque to drive the pump, the pump will not produce any output flow.

To determine the torque required by a hydraulic pump, use the following equation:

T = P × D / (6.28 × 12 × EM)

where: T

is torque, lb-ft, and

D is displacement, in. 3 /revolution

Pump displacement is provided in manufacturer's literature. Continuing with the example introduced above, if the pump has a displacement of 1.75 in. 3 /rev., required torque is calculated as follows:

T = 2000 × 1.75 / (75.36 × 0.80)

T = 58 lb-ft

Torque can also be calculated using the familiar horsepower equation:

hp = T × n / 5250

where:

n is shaft speed, rpm.

Substituting values from the example:

20 = T × 1800 / 5250

T = 58 lb-ft.

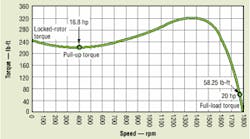

Electric motor torque signature

To understand the differences in power characteristics between an electric motor and internal-combustion engine, we'll first examine characteristics of a standard 3-phase electric motor. Figure 1 shows the torque-speed relation-ship of a 20 hp, 1800 rpm, NEMA Design B motor. Upon receiving power, the motor develops an initial, locked-rotor torque, and the rotor turns. As the rotor accelerates, torque decreases slightly, then begins to increase as the rotor accelerates beyond about 400 rpm. This dip in the torque curve generally is referred to as the pull-up torque. Torque eventually reaches a maximum value at around 1500 rpm, which is the motor's breakdown torque. As rotor speed increases beyond this point, torque applied to the rotor decreases sharply. This is know as the running torque, which becomes the full-load torque when the motor is running at its rated full-load speed — usually 1725 or 1750 rpm.

The torque-speed curve for a 3600-rpm motor would look almost identical to that of the 1800-rpm motor. The difference would be that speed values would be doubled and torque values would be halved.

Common practice is to ensure that torque required from the motor will always be less than breakdown torque. Applying torque equal to or greater than breakdown torque will cause the motor's speed to drop suddenly and severely, which will tend to stall the motor and most likely burn it out. If the motor is already running, it is possible to momentarily load a motor to near its breakdown torque. But for simplicity of discussion, assume the electric motor is selected based on full-load torque.

Note that Figure 1 shows a temporary large torque excess that can provide additional muscle to drive the hydraulic pump through momentary load increases. These types of electric motors also can be run indefinitely at their rated hp plus an additional percentage based on their service factor — generally 1.15 to 1.25 (at altitudes to 3300 ft).

Catalog ratings for electric motors list their usable power at a rated speed. If the load increases, motor speed will decrease and torque will increase to a value higher than full-load torque (but less than break-down torque). So when operating the pump at 1800 rpm, the electric motor has more than enough torque in reserve to drive the pump.

Torque behavior of engines

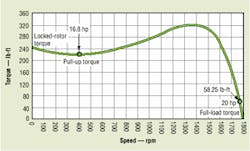

A gasoline engine has a dramatically different torque-speed curve, Figure 2, than an electric motor does. This means a gasoline engine exhibits a much less variable torque output throughout its speed range. Depending on their design, diesel engines with the same power ratings may generate slightly higher or lower torque at lower speeds than gasoline engines do, but diesels exhibit a similar torque curve throughout their operating speed range.

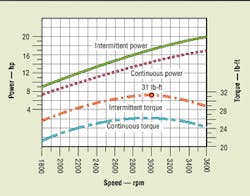

Prior calculations determined that 58 lb-ft of torque is required to drive the pump at any speed. Referring to Figure 2, the 20-hp gasoline engine develops a maximum torque of only 31 lb-ft — clearly not enough to drive the pump. This is because its 20-hp rating is based on performance at 3600 rpm. Maximum torque occurs at speeds near 3000 rpm, but is still well below the 58 lb-ft required by the pump. Even if the engine produced enough torque at this speed, power would still be inadequate due to the lower speed.

This is where the 2 1 /2 sizing rule comes from. An HPU requiring a 20-hp electric motor to drive the pump at 1800 rpm would require a gas or diesel engine rated at about 50 hp. Moreover, these values are based on an engine operating at its maximum torque and power ratings. However, manufacturers recommend that gasoline and diesel engines only operate continuously at about 85% of their maximum rated values to prevent seriously shortening of their service lives. So referring again to Figure 2, a 20- hp gasoline engine would develop just over 26 lb-ft of maximum torque, and only 24 lb-ft at 3600 rpm.

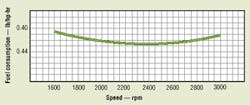

It is also interesting to compare this performance with fuel consumption. The fuel consumption chart, Figure 3, shows that a 20-hp gasoline engine achieves greatest fuel efficiency at about 2400 rpm, where it consumes just over 8.2 lb/hr (0.41 lb/hp 20 hp). At 3600 rpm, the engine would be considerably less fuel efficient.

Actions to be taken

By now, it should be clear that specifying a gasoline or diesel engine to drive a hydraulic power unit follows a different procedure than that for specifying an electric motor. If you are accustomed to specifying electric motors for hydraulic power units, you may be tempted to size a pump to be driven at 1800 rpm, then specify an oversized motor that can develop enough torque to drive the pump at this speed. This technique will produce a reliable power unit, but one that is relatively heavy, bulky, inefficient, and noisy.

Instead of following this procedure, any of several options should be considered. One would be to drive the pump at a speed higher than 1800 rpm. Pump literature for mobile equipment should list ratings at a variety of speeds. If it doesn't, consult the pump manufacturer. Driving the pump at a higher speed decreases its required displacement, thereby reducing its size, weight, and torque requirement. So operating the power unit at higher speed more closely matches engine performance to the application by increasing torque produced by the engine and reducing the torque required by the pump.

More specifically, operating the pump in our example at 2800 rpm would increase engine torque to more than 30 ft-lb and reduce torque required by the pump to perhaps 38 ft-lb. Although the engine torque still would fall short of that required, it obviously comes much closer to matching pump torque than when operating at 1800 rpm.

Designers may be tempted to run a gas or diesel engine at or near the speed at which it exhibits optimum fuel efficiency. However, an operating speed where the engine produces maximum torque generally takes priority. This is because if the engine doesn't generate enough torque at its optimum fuel efficiency speed, a larger engine would be required. But a larger engine consumes more fuel, which would defeat the purpose of trying to conserve fuel by operating at a specific speed.

In addition, pumps generally have a speed range at which they are most efficient. So even if an engine operates a few hundred rpm above or below its optimum fuel efficiency speed, torque produced and pump dynamics generally have a more pronounced effect on overall efficiency of the power unit. Therefore, the speed at which the gas or diesel engine operates should take all of these considerations into account.

As far as pump performance, many designs exhibit higher mechanical and volumetric efficiencies when operated at speeds greater than 1800 rpm. On the other hand, operating a pump at a speed higher than what it was designed for would reduce its service life. Therefore, it is important to choose a pump speed that offers the best combination of pump and engine performance.

Perhaps an even better alternative would be to provide a gear-box or other type of speed reducer between the engine and pump. Although this would add components to the power unit, it would increase torque and reduce speed while allowing both the engine and the pump to operate at their optimum speeds. The additional cost of the speed reducer may be offset by the lower cost of a smaller, lighter, and less-expensive engine.

Other considerations

Because gas and diesel engines do not exhibit the torque reserve of electric motors — especially when accelerating from rest — it is especially important that the pump be unloaded whenever the HPU is started. This can be done hydraulically, or mechanically through a centrifugal clutch or other type of drive element.

Finally, as with HPUs driven by electric motors, pump size — and, therefore, size of the prime mover — often can be reduced by incorporating accumulators into the hydraulic system. If the hydraulic system operates in cycles where full flow is needed only for brief periods, an accumulator can store hydraulic power during periods of low flow demand and release this energy when full flow is needed.

This article is based on information originally submitted by Ronald R. Gould, CFPE, former vice president/engineering, Advanced Lifts, Inc. St. Charles, Ill. Additional assistance was provided by Larry Schrader, global motion & control training manager, Parker Hannifin Corp., Cleveland.