By Steve Kopfman,

Wilkes and McLean Ltd.

Schaumburg, Ill.

Until modern times, the oceans and seas had been a place of solitude and serenity. However, it is estimated that harmful ocean noise created by man, specifically from ships, has increased 10 times from 1950 to 1975 and is now rising at an even more alarming rate.

Sound travels four times faster in water than it does in the atmosphere and also travels extremely long distances, causing noise from ships to reach marine animals faster than atmospheric noise would. Many marine species use sound to communicate, to locate food, and for mating purposes. The louder the oceans and seas become, the less ability these animals have to survive. Scientific data suggest that noise from ships significantly alters the behavior of many marine species and can cause groundings and beachings as marine animals try to avoid these devastating noises.

The detrimental effects of man-made sound on marine species also threatens future generations. Some marine species use sound to locate breeding sanctuaries in rivers and inlets, but this has been interrupted by multiple sounds from multiple sources. Noise-induced stress can also weaken immune systems of dolphins and whales.

Confronting the problem

Unfortunately, hydraulic systems are a major contributor to this man-made noise. Most ships have multiple hydraulic systems, which all contribute to this exponential increase in noise. Solutions to some problems will require a global effort to combat noise effectively. However, much can be done today on a ship-by-ship basis to reduce ocean-borne noise — especially noise generated by hydraulic systems. For example, instead of securing hydraulic lines with all-metal clamps, cushioned clamps with elastomeric inserts can prevent noise and vibration from being transmitted from hydraulic tubing to the frame and hull of the vessel. Elastomeric mounts can also be used to damp vibrations that would otherwise be transmitted from a hydraulic pump and electric motor to the vessel.

But these techniques address noise emanating from the hydraulic system. A more effective solution is to reduce the noise produced by it. Wilkes and McLean manufactures a noise and shock suppressor that easily can be installed in hydraulic lines to drastically cut down on the amount of noise generated by the hydraulic system.

The inline suppressor reduces the pressure ripple generated by pumps by smoothing out the peaks and valleys of the pressure waves. The suppressor is bidirectional, so it also cushions intermittent hydraulic shock that can occur when valves close suddenly or actuators bottom out or encounter an immovable load.

How it works

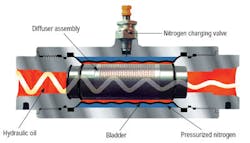

The suppressor consists of three concentric, cylindrical metal noise diffusers inside a nitrogen-charged tubular rubber bladder. The inner diffuser has 12-in. diameter holes cut into it. A second layer is a coil spring that helps support a thin outer diffuser, and an outer diffuser is perforated by more than 4000 132-in. diameter holes. These holes are small enough to prevent the surrounding bladder from extruding into them.

Pulsations enter the suppressor and then pass through the diffusers — a total radial distance of only 14 in. — and strike the bladder, which typically is charged at 50 to 60% of the hydraulic system operating pressure. The bladder deflects each time it is hit by a pulsation, and this slight deflection absorbs and reduces pressure pulsations and any shock waves. The bladder’s large area, its ability to oscillate at high frequency, and short travel distance combine to absorb pulsations with frequencies above 600 Hz. With the pulsations reduced or eliminated, they can no longer be transmitted through the hydraulic system, thereby reducing noise generated by the vessel’s hydraulics.

State-of-the-art quiet

Noise Control Engineering, Billerica, Mass., has worked extensively on the design of quiet ships. Michael Bahtiarian, vice president, explains, “Most oceanographic research vessels require low levels of radiated noise in order to use acoustic instrumentation effectively. For Example, 40-day endurance Fishery Research Vessels for the National Oceanic and Atmospheric Administration have been designed to conduct fish stock assessment using acoustic methods. In order for such tools to be used, the levels of underwater sound had to be reduced significantly. The FRV-40 shown on page 22 meets underwater strict noise limits from the International Council for the Exploration of the Seas (ICES).”

Bahtiarian adds, “To meet ICRA noise limits, a ship requires a carefully designed propeller, vibration isolated machinery, and an acoustically insulated hull among other treatments. Machinery isolation includes diesel-powered generators, large pumps, air compressors, HVAC systems, and hydraulic power units. Vibration isolation of the HPUs alone may not silence this equipment because the (pulsation) noise easily travels down the hydraulic piping. Further, it can travel in both directions of flow. NCE engineers have seen such noise travel down static gravity lines as well. Careful location of the hydraulic lines will be necessary, but the use of the Wilkes and McLean suppressor helps reduce the effects.”

In fact, it’s not unheard of to see a noise reduction of 17 dB or more.

For more information, contact the author at [email protected], call (847) 534-2000, or visit www.wilkesandmclean.com.