To add some life to its owls, workers Clippard turned to their stock and trade — pneumatics. By mounting each of several plastic owls to a vertically mounted air cylinder inside a section of 8-in. PVC pipe, the dummies pop up on command, then retract back out of sight. Faced with these more dynamic dummy owls, the pigeon problem has flown the coop.

Rich Boutell, engineering manager, explains, “We determined that a 12-in. stroke would be long enough to hide the plastic owl within the PVC tube when the cylinder is retracted. Normally, a single-acting cylinder with no return spring would do the job, but because the owl and rod assembly are so light, we figured the owl might not retract all the way back into the tube from gravity alone.

“Normally, this would lead us to use a spring-return cylinder, but a 12-in. stroke, single-acting cylinder is almost 22-in. long to accommodate the return springs. Because the cylinders must be vertically mounted, we were concerned about having an assembly protrude that far down from the ceiling.”

Clippard personnel solved the problem by instead using 12 in. stroke double-acting cylinder, which is 7 in. shorter than its single-acting counterpart. To simplify installation, Clippard personnel decided to use an inexpensive circuit that actuates a double-acting cylinder as if it were single acting.

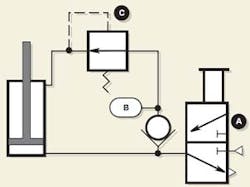

Referring to the schematic, compressed air flows to normally closed 3-way toggle valve A. The outlet of this valve is connected to the cap-end cylinder port. A connection is also made through a check valve to a volume tank and inlet of pressure regulator C. The outlet of the regulator is connected to the cylinder’s rod-end port.

Shifting valve A to open routes air through the check valve, charging the volume tank B, with compressed air. Air also flows through the regulator (adjusted to a pressure less than the supply) and into the rod end of the cylinder. Simultaneously, air at supply pressure flows into the cap end of the cylinder. Because the pressure is greater on the cap end side of the cylinder, the piston rod extends, which raises the owl.

Shifting valve A closed allows the air in the bottom piston chamber to exhaust to atmosphere. But the check valve prevents air in the volume tank from flowing back through valve A. The regulated air still applied to the rod end of the cylinder applies pressure to the rod end side of the piston. This retracts the rod, thereby lowering the owl.

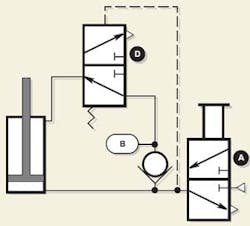

An alternate circuit uses an air piloted, normally open 3-way valve, D, instead of the regulator. When valve A is actuated, air flows through the check valve and fills the volume tank. Pressurized air also flows through the pilot line to close valve D. This opens the rod-end port of the cylinder to atmosphere. At the same time, air flows into the cap end of the cylinder, extending the piston and raising the owl.

Toggling valve A closed allows air in the cylinder’s cap end to exhaust to atmosphere. This action also terminates pilot pressure to valve D, so it opens the air in the volume tank to the rod end of the cylinder. As a result, the piston retracts, lowering the owl.

Boutell mentioned that to keep the pigeons away, the valve is periodically toggled open and closed throughout the workday. “Eventually, we’d like to install a motion detector and timer on the roof. That way, whenever a pigeon landed on the roof, the motion sensor would send a signal to a solenoid valve, which would pop up the owl. After a while, the timer would toggle the valve back closed, and the owl would again disappear into the pipe. But the problem seems to be solved, so if we go the higher-tech route, it’ll be mainly for our own satisfaction.”

For more information on Clippard's valves, cylinders, and other components, call (513) 521-4261, or visit www.clippard.com.