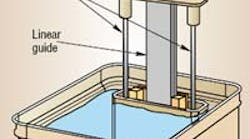

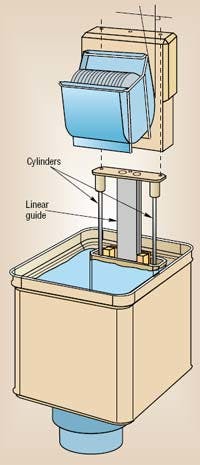

Strasbaugh, San Luis Obispo, Cal., builds processing equipment used in the fabrication of semiconductor integrated circuits. One operation on their Symphony Model chemical/mechanical polisher (CMP) involves lowering a cassette of silicon wafers into a rinse tank, then raising it. This sounds simple enough, but a cassette can contain as many as 25 wafers etched with patterning for advanced- memory or microprocessor components. A full cassette of wafers can be worth more than $1 million, so smooth, precise, and reliable elevator motion is important — for both operating and aesthetic reasons.

Older Strasbaugh machines had used a servo motor and precision ball-screw to raise and lower the cassette in incremental steps. When a new design eliminated the need for steps and called only for top-to-bottom travel, Dave Halley, senior design engineer at Strasbaugh, decided to investigate the use of air cylinders for this movement to reduce the cost.

The cylinders had to stroke 12 in. to immerse the cassette fully in the rinse tank and then to raise it to interface with a handling robot. Because this machine operates in a clean-room environment, no lubricants or particle-generating mechanisms can be present. In addition, the cylinder is exposed to harsh chemicals — for example, polishing slurries are present that can have pHs that range from a very basic 1.5 to a highly acidic 13.

From experience, Halley knew that their inherent stiction would prevent most air cylinders from starting and stroking with the high degree of smoothness required in this application. He also knew that typical elastomeric seals could not meet the cleanliness specifications, nor could other materials used in typical air cylinders survive in the chemical environment. These limitations led him to Airpel pneumatic cylinders, built by Airpot Corp.

Airpel cylinders have no elastomeric seals between the piston and cylinder walls or between the rod and cylinder head. Instead, the Airpel design places a precision carbon/graphite piston inside a Pyrex glass cylinder — with a 0.0005-in. air gap surrounding the piston. The piston floats inside the barrel using air-bearing principles. Instead of a rigid connection between piston and piston rod, a biaxially pivoting arrangement allows the piston to maintain its orientation despite lateral loading. These techniques dramatically reduce both static and dynamic friction, without lubrication. As little as 0.1-psi can initiate movement in unloaded Airpels.

Rated for 100-psi pressures, with an operating temperature range from –65° to 150° C, Airpels are well suited for applications that call for very smooth motion, low speeds, or short strokes, or where only low pressure is available. But they also will produce the same range of motions as conventional small air cylinders. To make the cylinder more rugged, Airpot adds a stainlesssteel, impact-protection sleeve over the glass barrel, with a gap between the two. This protection lets the cylinder withstand impact testing with a 10-lb load and continue to function.

Although Airpel cylinders performed well during Strasbaugh’s initial tests, the elevator assembly did not quite meet the stringent motion requirements. Friction in the linear-guide mechanism and the variation in loads between full and empty cassettes resulted in motion that still was too irregular. Halley decided to see if he could actuate the CMP cylinders with water and capitalize on its incompressibility to achieve the smooth motion he wanted.

This decision presented another problem. To meet the cleanliness requirements of the CMP machine, pressurized deionized water had to be used to drive the cylinder. And deionized water tends to corrode many materials. In particular, it eats aluminum pretty quickly. To circumvent the corrosive effects of the deionized water, Airpot made some design modifications on the standard Airpel. These amounted to replacing the nickel-plated aluminum piston couplings and cylinder heads with stainless steel components. To test the modified cylinder, Strasbaugh used a 5-lb load and canted it at a 4° angle, adding side loading to exaggerate wear potential. With raise/lower speed set at 1 in./sec, the modified, water-powered Airpel was cycled more than a million times with no degradation in travel rate. (A small amount of deionized water leaked past the gap around the piston and was collected in a drain pan for disposal.) Testing on the actual elevator assembly followed, and the water-actuated cylinder met all design and performance specifications.

Dave Halley, of Strasbaugh, and Mark Gaberman, president, Airpot Corp., Norwalk, Conn., described this application.