Packaging needs to do much more than simply secure its contents. Wholesale packaging in particular plays an important role in conveying information on the product. On the one hand, legal stipulations regarding labeling have to be observed, such as the ingredients of food and warnings on tobacco products. On the other hand, an advertising message is also conveyed. The barcode for electronic checkouts is also now mandatory.

Emkon, Kirchlinteln, Germany, manufactures machines that fulfil the requirements of modern packaging. One new product is its Emkon.shark packer. The Shark is intended for handling bags and foldable boxes. Flexibility is a must for the material being used and for the package sizes, so the machine must be designed for quick changeovers. Packaging material is pulled from a roll, cut to size with a specially designed knife, and closed with the required number of products inside using hot or cold glue.

Sensors offer precision

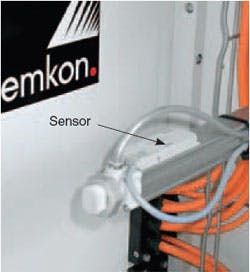

In order to glue different widths of the packaging materials accurately, the slides that move the glue heads must be precisely controlled. This is where Bosch Rexroth pneumatics comes in. A miniature cylinder moves the glue head, which must be moved out and back at a consistent speed. Rexroth’s integrated SF1 cylinder sensor permits stopping the cylinder anywhere along its stroke.

Stopping points are entered into a control program and set at the required locations along the glue track. These points can be changed anywhere along the track without having to make any physical adjustments. The cylinder always moves the total distance and applies the glue over different lengths, depending on the program.

As shown in the photo, the SF1 sensor attaches directly to the cylinder. This reduces the number of moveable parts, which simplifies commissioning and maintenance. It also drastically reduces time required to change glue application profiles, and saves space, so optional assemblies can be incorporated when desired.

Compared with a conventional proximity sensor, which has to be manually aligned, no inadvertent setting can occur. Digital switching points also reduce required cabling, which makes for a simpler construction. In systems that are difficult to access, switching points can also be set by means of a handheld remote control. The SF1 generates a 0- to 10-V analog signal that the machine’s control reads for monitoring glue head position.

A look at the sensor

The SF1 is available for analog or digital cylinder condition monitoring, for specific position monitoring, or to measure the entire stroke. Available on Rexroth OCT cylinders with strokes from 65 to 500 mm, it is integrated into the design, making it a functional component cylinder.

The analog version of the SF1 enables analog depiction of the entire cylinder stroke, using an operating voltage of 15-30 V. The digital version supports two or four switching points, using simple “select” and “set” buttons on the attached electronics. Digital swi tching point set t ing i s done through a simple teach-in procedure, and many intermediate positions can be recorded.

The SF1 meets IP50 protection and can be used in ambient temperatures from 32° to 122°F. Repeatability is ±0.1 mm and accuracy is stroke/1000.

Automation versatility

“Our increasingly modular system is especially interesting for customers that, for example, wish to introduce new products into a specific market and later sell them into other markets using different packaging,” says Andreas Dittrich, managing director of Emkon. “Decisive factors here are the different legal stipulations of the individual markets and the specialized demands on the product packaging.”

A fast tool change between different packaging types and sizes is also of interest for prototype and other short-run production applications.

For more information on Bosch Rexroth’s line of pneumatic and other automation products, visit www.boschrexroth-us.com.