The cost of air has become an increasingly important consideration in today's competitive manufacturing environment. Electrical cost is the most expensive part of creating compressed air, and the higher the pressure, the greater the cost. The cost to compress air to 100 psig depends on the electrical rate ($/kW-hr); type and condition of the compressor; and the type and condition of the piping system. Electrical cost can range from $0.13/1000 ft3 to as high as $0.40/1000 ft3. Consequently, anything you do to reduce the cost of compressed air pays for itself over and over.

In general, if you reduce a system's operating pressure by 2 psig, you can save 1% in overall operating cost. This savings can start at the point of use by revisiting your existing applications to re-evaluate required pressures with the intent of reducing them.

Almost a free lunch

One of the most common applications where you can realize savings is a standard air cylinder moving a load into position and then resetting itself. Common practice is to operate cylinders at the same pressure for extension and retraction. However, by applying a dual-pressure technique, you save energy by using high pressure only where it is needed.

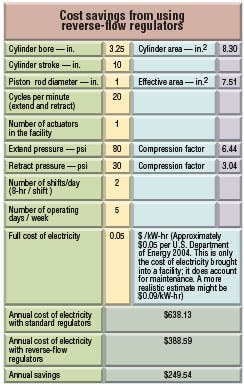

For example, a cylinder operating at 80 psig for both extension and retraction might need only 60 psig to extend and just 30 psig to retract, with no reduction in speed. The savings in this case can be hundreds of dollars a year per cylinder, as shown in the table. The example in the table uses a 31⁄4-in. bore 10-in. stroke cylinder that cycles 20 times/min at 80 psig for extension and retraction. Based on an electrical rate of $.05/kW-hr, it would cost $638.13 per year to operate this single actuator. However, if you reduce the pressure to only 30 psig just for retraction, the estimated cost to operate this cylinder drops to $388.59 — an annual savings of $249.54 for this single actuator.

How it's done

An easy way to achieve this savings is by using a reverse-flow regulator between the directional-control valve and the actuator. Simply installing a $40 regulator can save nearly $250 per year. The challenge is finding a regulator that limits pressure for extension but presents no flow restriction during retraction.

Not all regulators are capable of this function. Regulators with a piston or a rolling diaphragm construction tend to perform well in this application because of their long life. However, flat diaphragm-style regulators should not be applied in these applications unless a bypass check valve is installed because the diaphragm is susceptible to rupturing from repeated stress.

Rick Hand is with Parker Hannifin's Pneumatic Div. in Richland, Mich. For more information, call (269) 629-5000 or contact him at [email protected].