By Michael R. Horgan, associate editor

The entertainment industry realized long ago that movies and television shows about animals had a certain appeal to a large audience. Look at the success of Lassie, Rin-Tin-Tin, Benji, Morris the Cat, Flipper, Gentle Ben, and even the shark in “Jaws.” People love animals. While it may have been an easy job training Lassie to save Timmy each week, it proved to be a tougher job creating a fulllength feature film about a 6000-lb whale and his relationship with a small boy.

Officials at Warner Bros. had a brilliant idea: let’s make a movie about a whale in a marine park and the little boy who tries to save the whale’s life. It will have small children, big animals, lots of action; it’ll be a hit. That’s exactly what it was, too. Warner Bros. did what it set out to do, but it wasn’t easy.

While the idea of a movie about the cute but massive whale proved to be a huge success, one thing puzzled its makers at the very beginning: How do we get this monstrous animal to do these phenomenal tricks on cue? The answer was simple. All we have to do is build a robotic whale that looks exactly like a real one.We control its movements, make it swim when we want, make it jump when we want, make it turn around when we want. And we can do it all over if we need a re-shoot. Oh, but the key is that the robot must really look like a whale in all aspects.

While the concept of using a robotic whale solved their problem, they subsequently encountered more problems. First of all, is it even possible to build such a creature? Secondly, who builds these creatures? Finally, how in the world would such a creature be powered?

After extensive research, Warner Bros. found out it could indeed be done. They then contracted Edge Innovations, a Palo Alto, Calif.- based special-effects company, to build this character. How to power the robotic whale then became the problem of Edge Innovations.

Getting started

“These things never work.” This was the comment by one of the directors when he was told that nearly half of the shots would involve a robotic whale. In the past, the whale would have been mounted on a track or pulled by cables. But this would definitely limit the movements available. It was important to the producers for Willy the whale to look realistic, but it may have been even more important for him to move realistically. A track or cable system would not have allowed for smooth movement. Engineers at Edge Innovations decided to use electronics and servohydraulics to control the movements of the hightech stand-in whale.

In order for the robotic whale to move like a real whale and look realistic, engineers at Edge had to research whales. “We studied videos of whales that depicted their movements so we could mimic them,” said Ty Boyce, electrical and mechanical engineer in charge of hydraulics and electronic systems design for Edge Innovations. “The model whale had to look and act exactly like a real whale. We had to make the weight and buoyancy similar to a real whale.

“We didn’t guarantee to the production company that the whale would swim like a real whale,” continued Boyce. “But we came up with a winner, and delivered more than what they expected.”

Edge Innovations is divided into two groups: engineering and modelmaking. The company did all of its own circuit board layout using microprocessor programming. Even before beginning this huge task, all components were theoretically analyzed, calculated, and proven on simulation hardware by Edge engineers, so when it came time to build, there were no unexpected surprises.

Actually, Edge used two different types of models. The first, a fullbody, free-swimming servohydraulic model, had fluid lines painted the same color as the water, so viewers could not see them. The second type of model was a dorsal back, which was built similar to the full-bodied model but the bottom portion contained no moving parts — it was there for structural purposes only. The dorsal back model was used for specialeffect shots, while the full-bodied whale was used when the entire whale needed to be in the shot. Four miniature whales were also used, but these electronic devices were remote controlled by divers using joysticks.

The full-bodied model had 14 axes of movements; all hydraulically controlled. Hydraulic cylinders and valves were used to control each eye as it opened and closed, and moved front to back; the tail and head both went up and down and side to side; the jaw opened and closed; the pectoral fins moved up and down and rotated; and the blowhole also was hydraulically actuated. It took five “puppeteers” to control Willy the robotic whale, which was powered by two 100-hp hydraulic power units. About 40% of the shots involving the whale in the movie were filmed using the model whale. The other 60% used a real whale named Keiko.

The movie was filmed on location in an amusement park in Mexico City. “We put the robotic whale in the same tank as Keiko, so we had some environmental concerns to deal with,” said Boyce. “We used a biodegradable, nontoxic oil, which meant we had to get special clearance from the pump manufacturers. We still took all efforts to minimize contamination. Leakage was not a problem since we used doublesealed quick disconnects.”

Most hydraulic components, ranging from valves to fittings, had to be specialized. While time and money dictated that they couldn’t use stainless steel in most cases, designers did use stainless steel in critical areas where rust could have been a problem. All working, moving parts were stainless steel. “We weren’t convinced anybody could do what we wanted them to do," said Boyce. “But they (component suppliers) worked with us, provided technical knowledge, and the manufacturers built into their products to take care of our specific needs. Most people know what a servovalve is and how to hook it up, but designing a complete system is so much different. That’s where our vendors stepped in. We couldn’t take off-the-shelf components; we had to have them customized.”

Movie Star

Some vendors triple tested their components before even releasing them to Edge. Tests were conducted on the hydraulics, the electronics, and the final assembly.

Although Boyce has a technical background, he admitted there were times he called for help. “If I don’t think I know something, I won’t hesitate to find someone who does,” he said. “We have a strong working knowledge so we can communicate with specialists. There’s no list — no text — you can go to for answers. That’s why cooperation from vendors is so important.”

A big splash

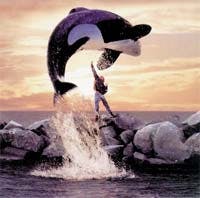

If you’ve seen the movie, you will undoubtedly remember one scene where Willy leaps over a breakwall on which the little boy is standing. Movie producers realized they would not only have problems getting a live whale to make this jump, but they also would face protests from animal rights activists. So it may come as no surprise that none of that scene involved a live whale.

Of course, the questions arose: How do you make this shot? Do you make the jump with the full-bodied look-alike Willy? How do you justify taking a chance on damaging or possibly destroying this million-dollar creature?

The answers: a computer-generated model was used in conjunction with the model whales. The computer- generated model is shown as the whale exits the water, followed by a computer image of a whale’s backside. As the whale moves over the boy, a shot shows the model Willy suspended by a crane. The final part of the scene shows the whale in a splendid splash as it hits the water. The splashdown was also a computer- generated image.

Another scene where the servohydraulically controlled model Willy solved producers’ problems was when the whale was being trans - ported. A few scenes show the whale being transported by truck — similar to trucks that carry several automobiles. Obviously producers couldn’t use a live whale. So the model Willy was used with a hydraulic hookup. A fluid line was run between the whale and a pump on a trailing truck that is just outside the view of the cameras.

Cosmetics

In addition to creating a creature that moves like a real whale, engineers at Edge Innovations were also faced with the task of making it look like a real whale. “The key to making the whale look realistic is how the skin moves when the whale moves,” said Boyce. “It’s made of a type of urethane so when the eye moves, or the head moves, so does the skin.”

One area that deserved special attention was the whale’s eyes. With extreme close-ups of the animal’s eyes appearing several times throughout the movie, engineers designed the eyes with lubrication to give them a watery look.

“We did all of the work on the whale here at Edge,” said Boyce. “Our core team of about 10 people not only designed the hydraulic system, but also incorporated the programming, using finite element analysis and mechanical design, as well as all of the whale’s cosmetic makeup. Integration of all of these is important; everyone learned how to do more than one job because we couldn’t afford to have people on staff to do just one thing.”

Conclusion

As the cinema becomes more realistic, movie producers need to find more ways of visually imitating reality. In this case, the old way of making the robotic whale move would have been through the use of cables or tracks. However, because the whale was the primary character in this film, much more precise, smooth, and accurate movements were necessary to make audiences believe they were watching a real whale.

Edge designers realized that electrohydraulic motion control provided all of the advantages necessary for the film: low noise, compact size, required horsepower, leakproof, tightly sealed from the environment and corrosion, and the removal of heat. With teamwork among themselves and with hydraulic component manufacturers, they help produce a blockbuster film with an servohydraulically powered movie star.